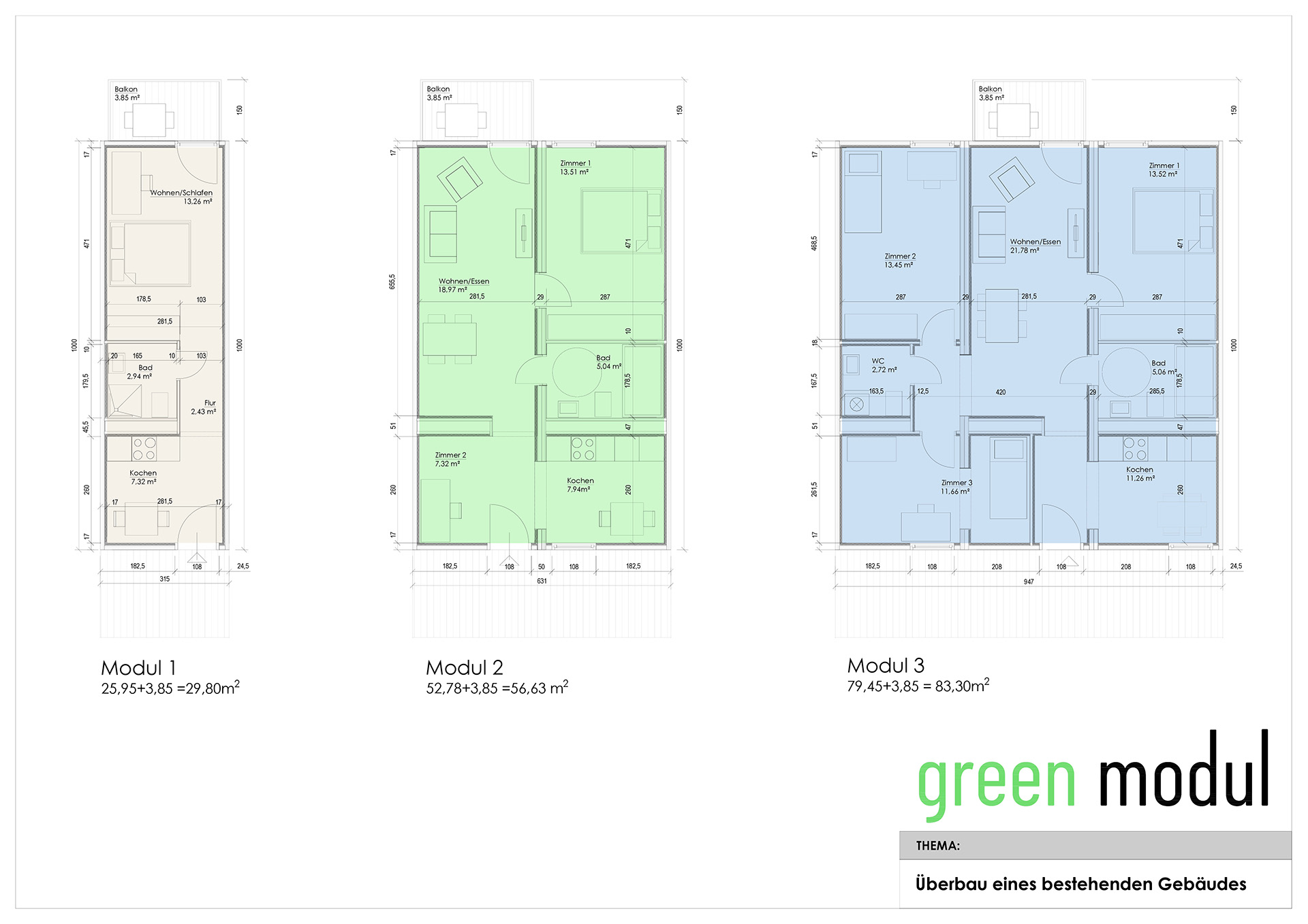

3D-Living-Module with load-bearing structure made of BBS panel (CLT)

We are a manufacturer of residential modules with a load-bearing structure made of BBS Binderholz (CLT) sandwich panels.

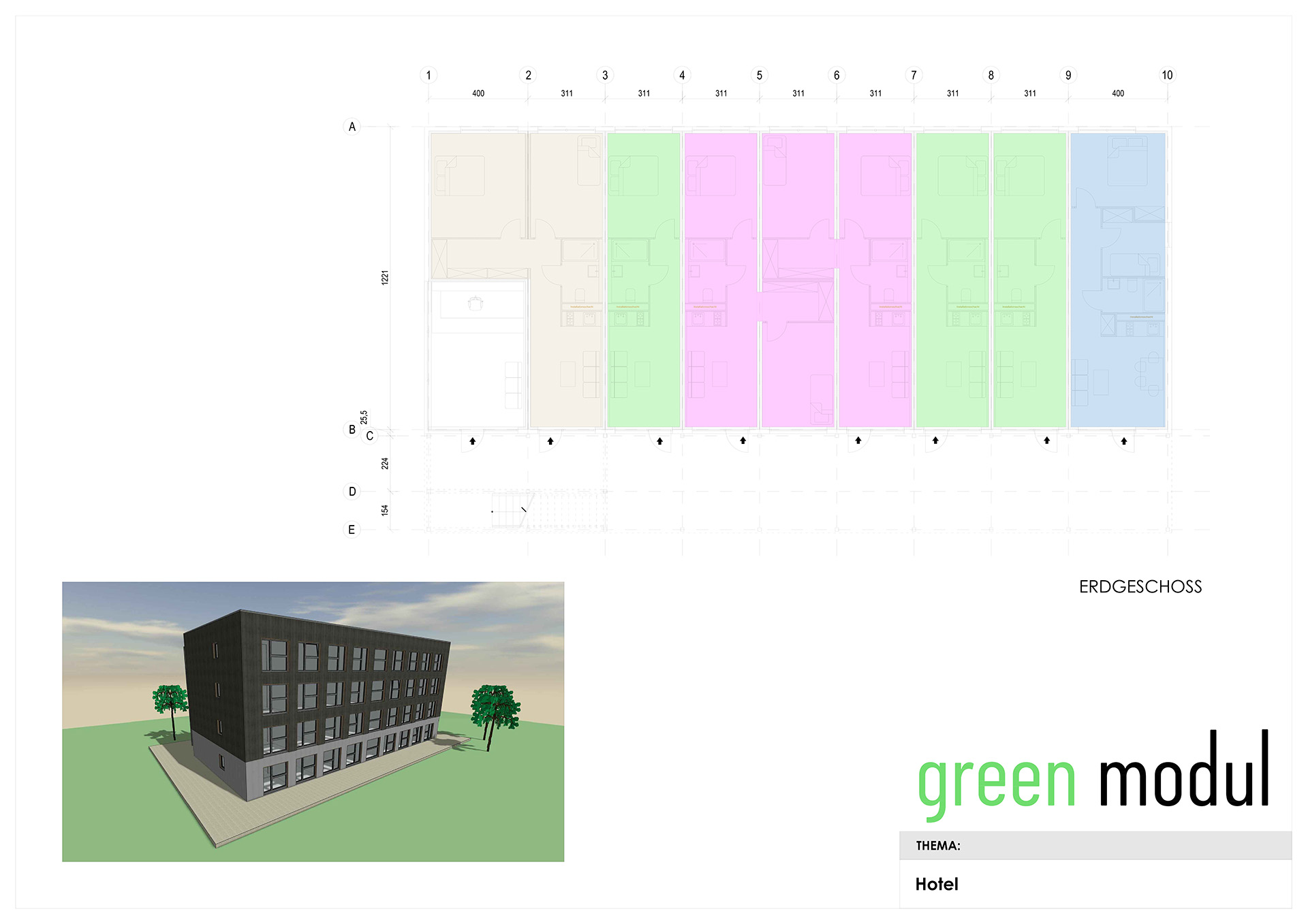

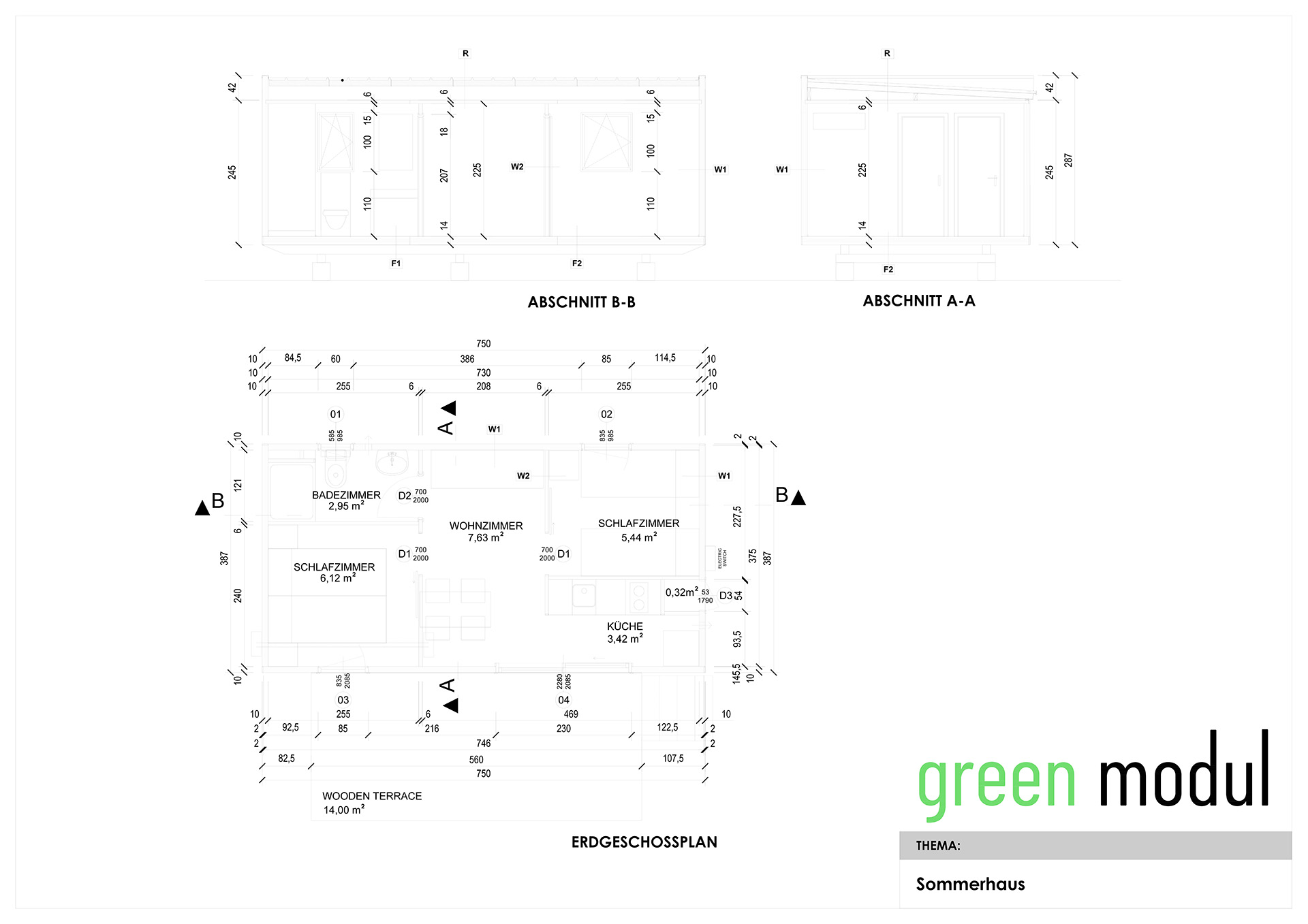

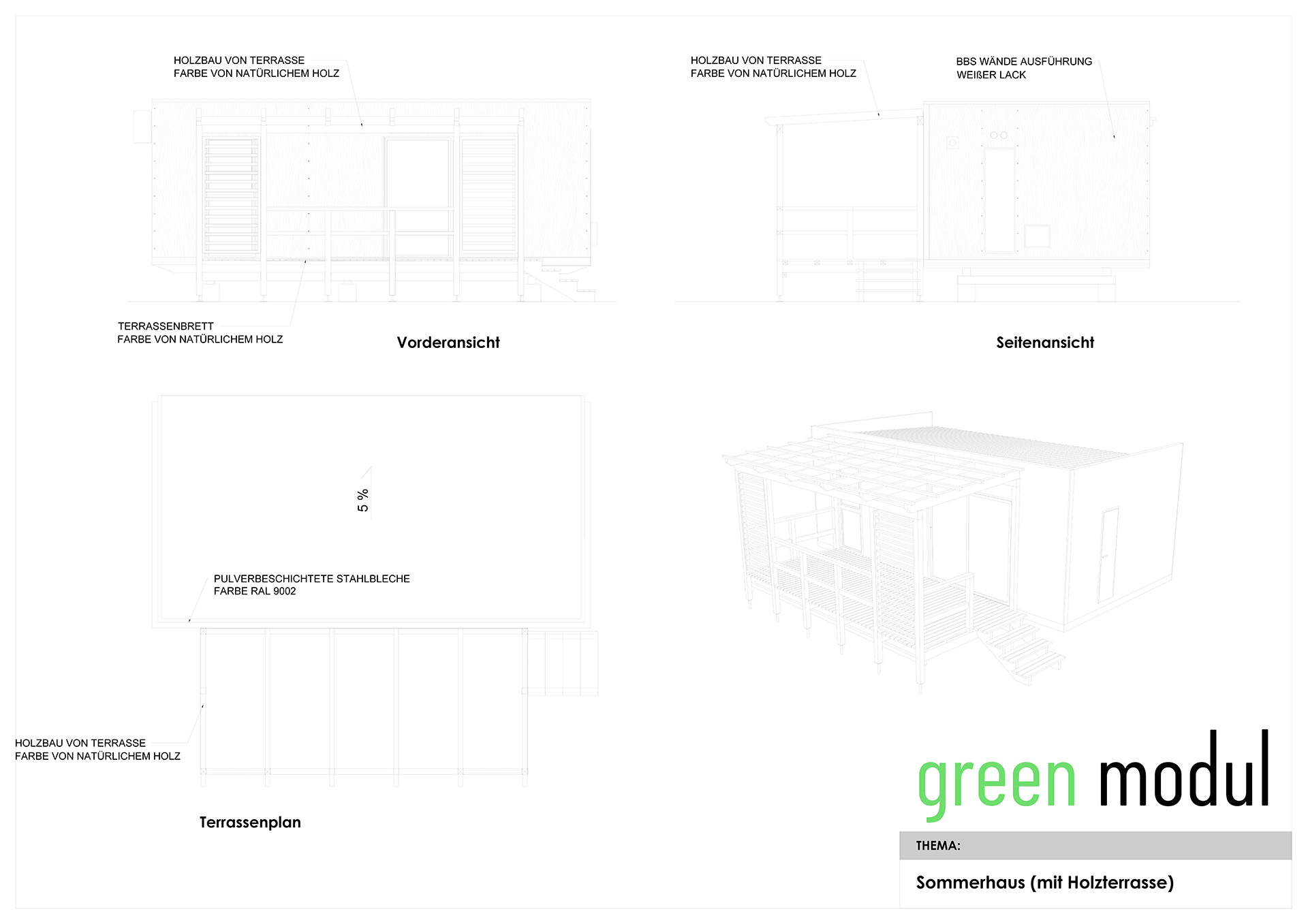

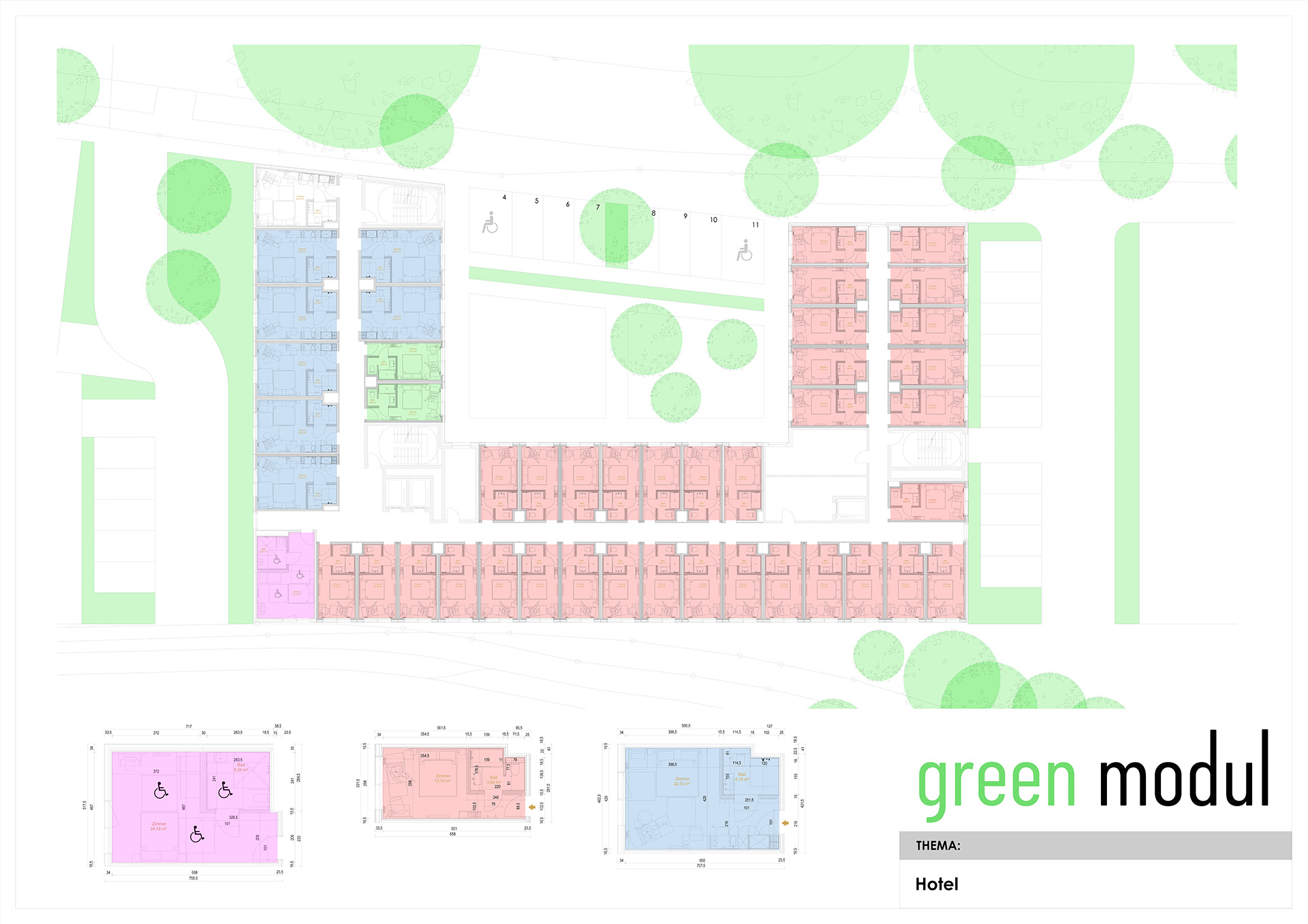

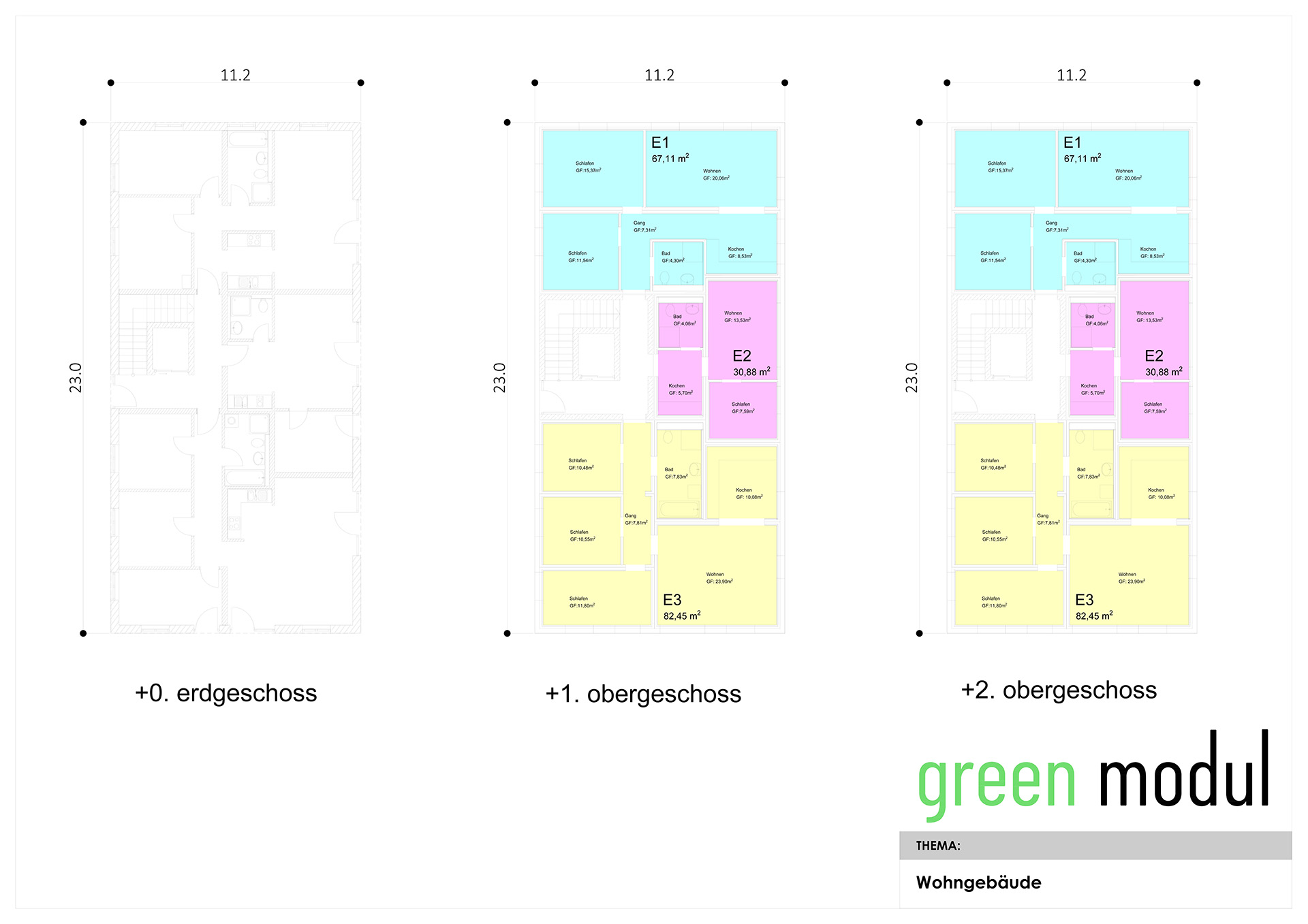

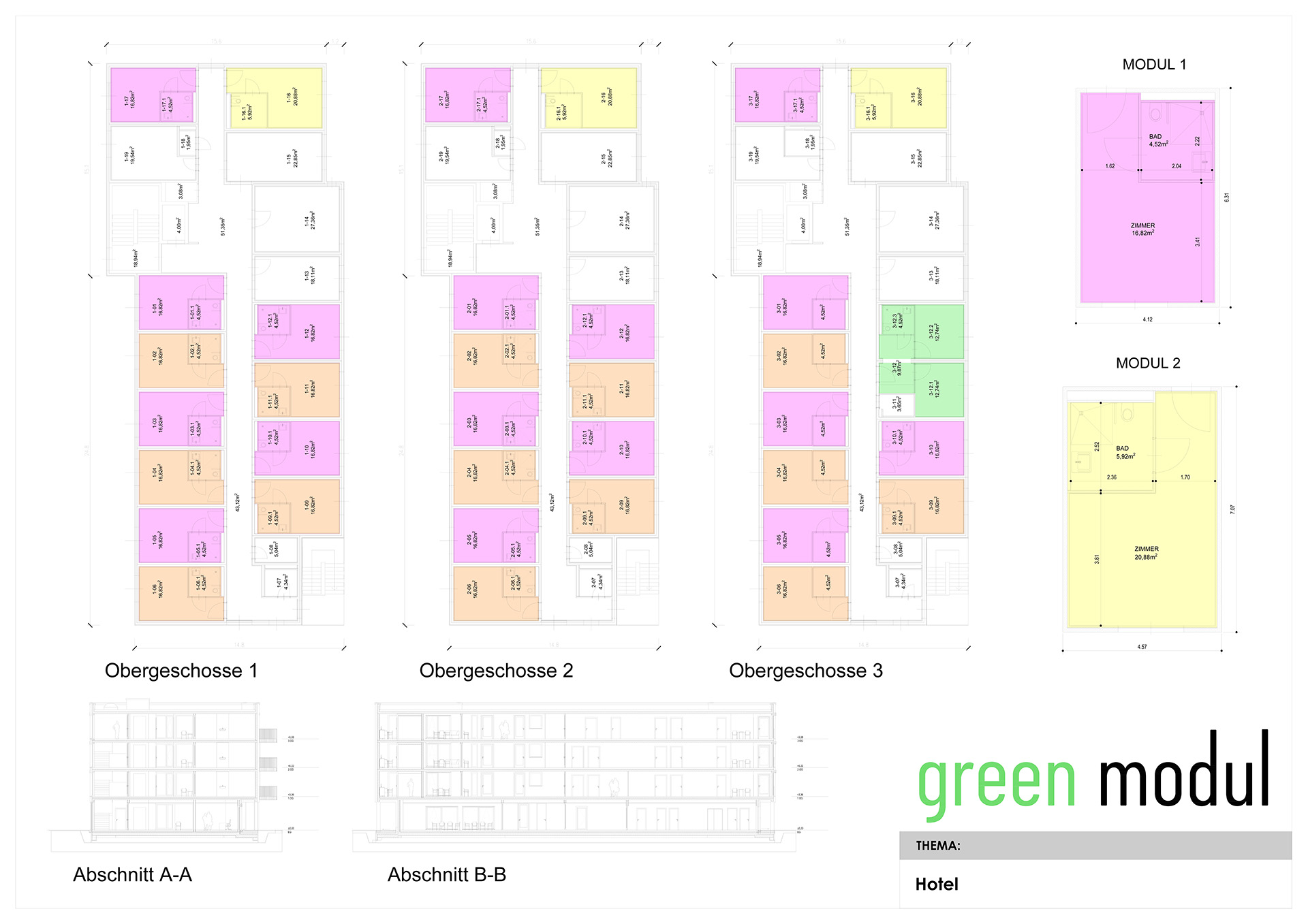

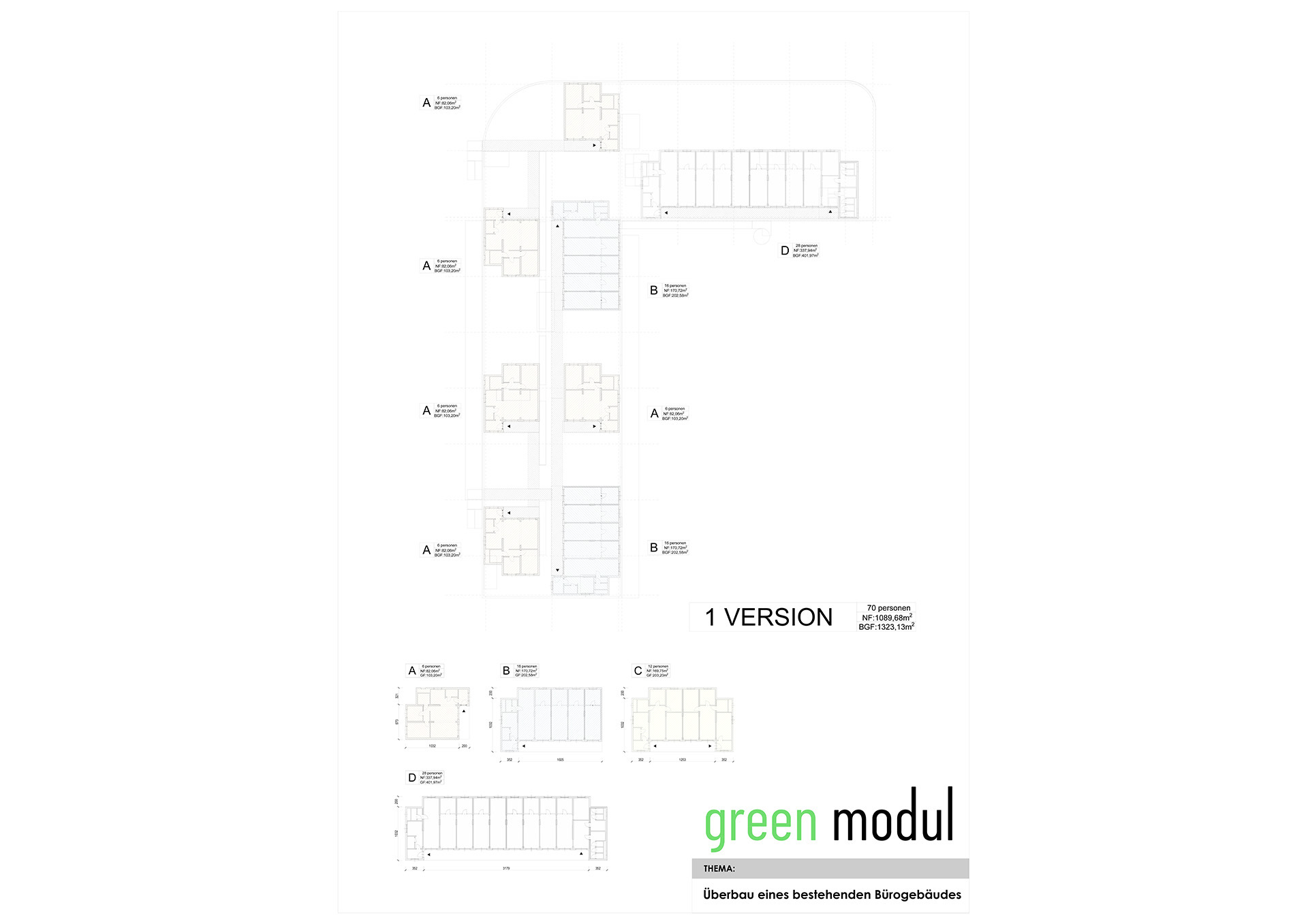

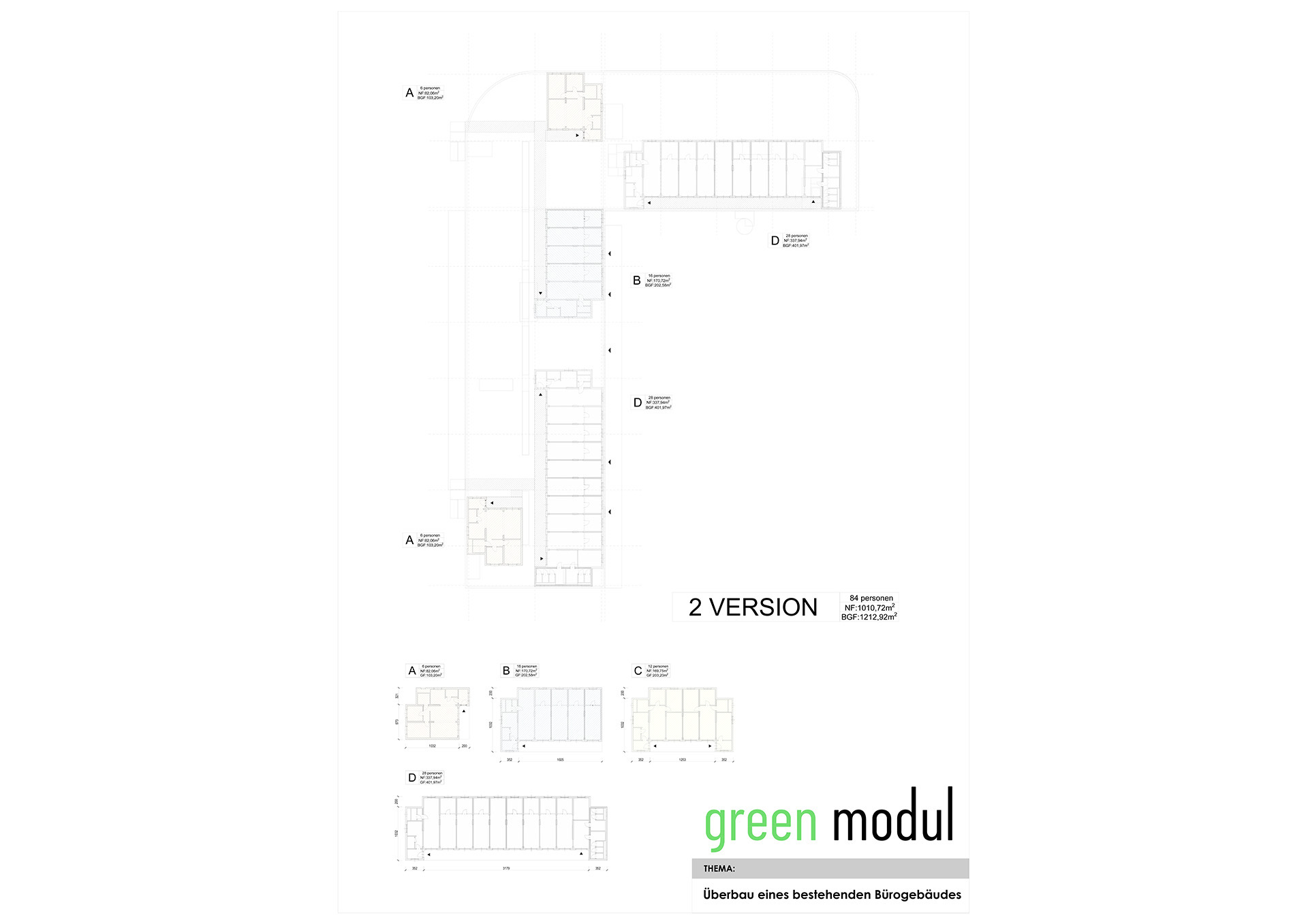

The use of this technology allows us to create buildings that are extremely attractive in terms of architecture due to the lack of restrictions on the dimensions and number of floors of buildings.

Our BBS Sandwich Panel (CLT) product is an independent, durable and stable structure that is weatherproof and offers exceptional performance in terms of heat, sound and fire protection.

Cross laminated timber BBS and BBS XL are among the solid wood construction methods

This cross laminated timber is a solid, flat wood product for load-bearing purposes. It is used as a plate or as a slice element.

Our product is characterized by:

Non-flammability parameters according to REI 120

Confirmed by the fire resistance parameter obtained during the tests up to the value of REI 120 and higher

IFT acoustic certificate

Confirmed by the high level of sound insulation of the partition walls obtained during the tests

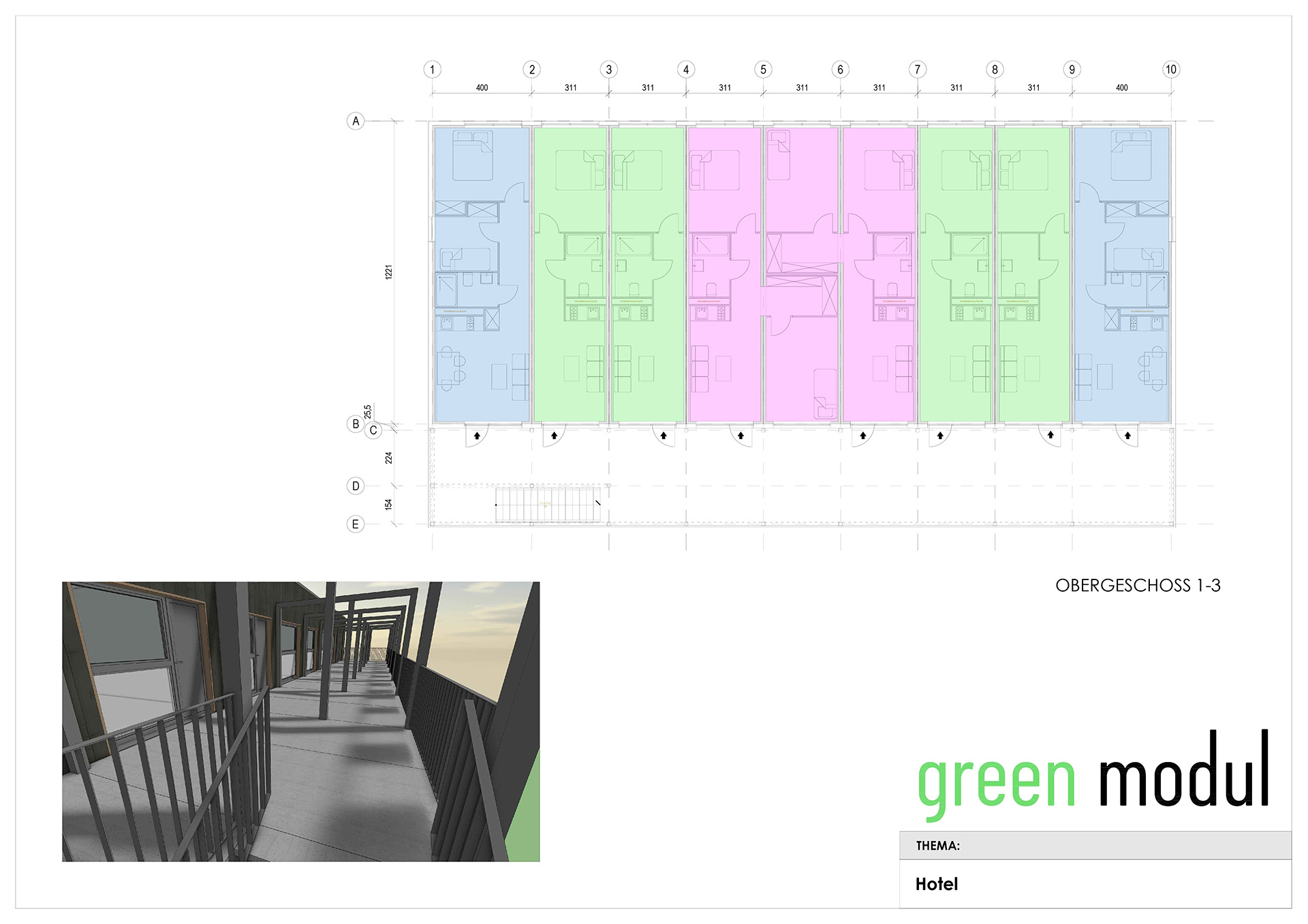

Buildings with up to 12 floors

Finished structure made of sandwich panel BBS (CLT)

Advantages of modules made of sandwich elements BBS (CLT)

The elements of the module structure achieve a high fire resistance parameter. Upon contact with fire, a layer of carbon forms on the surface of the BBS sandwich panel (CLT), which significantly slows down the combustion process. Depending on the thickness of the BBS board, the structure achieves the fire resistance class / fire resistance parameters REI30, REI60, REI90 and even REI120.

A correctly assembled module construction has a high level of airtightness due to the perfect fit of the components and reduces the formation of heat and sound bridges.

The BBS sandwich panel (CLT) is extremely rigid as a full panel. No additional struts need to be used in the construction of the modules. Depending on the thickness of the panels used, buildings with up to a dozen floors can be erected without additional reinforcement structures.

A characteristic feature of the BBS Sandwich Panel (CLT) is the so-called phase shift, i.e. the heat that arises on the outer surface of the module, e.g. through heating from solar radiation, only reaches the interior of the room after several hours.

The module is a diffusion-open structure, ie it regulates the room humidity well. The wall can absorb a certain amount of moisture and the excess is discharged to the outside. When the humidity drops, the moisture inside is released.

Short investment realization time. The entire production process of BBS sandwich panel modules (CLT) is carried out in our factories “under the roof”. This enables inline production with full control over every process.

The prefabrication of components – modules – in the factory has a positive effect on the final dimensional assessment of the accuracy of shipping units. It also reduces the additional costs associated with possible error corrections on the construction site and in subsequent operations.

A building made of 3D modules produced by us can be erected at any time of the year and in any weather.

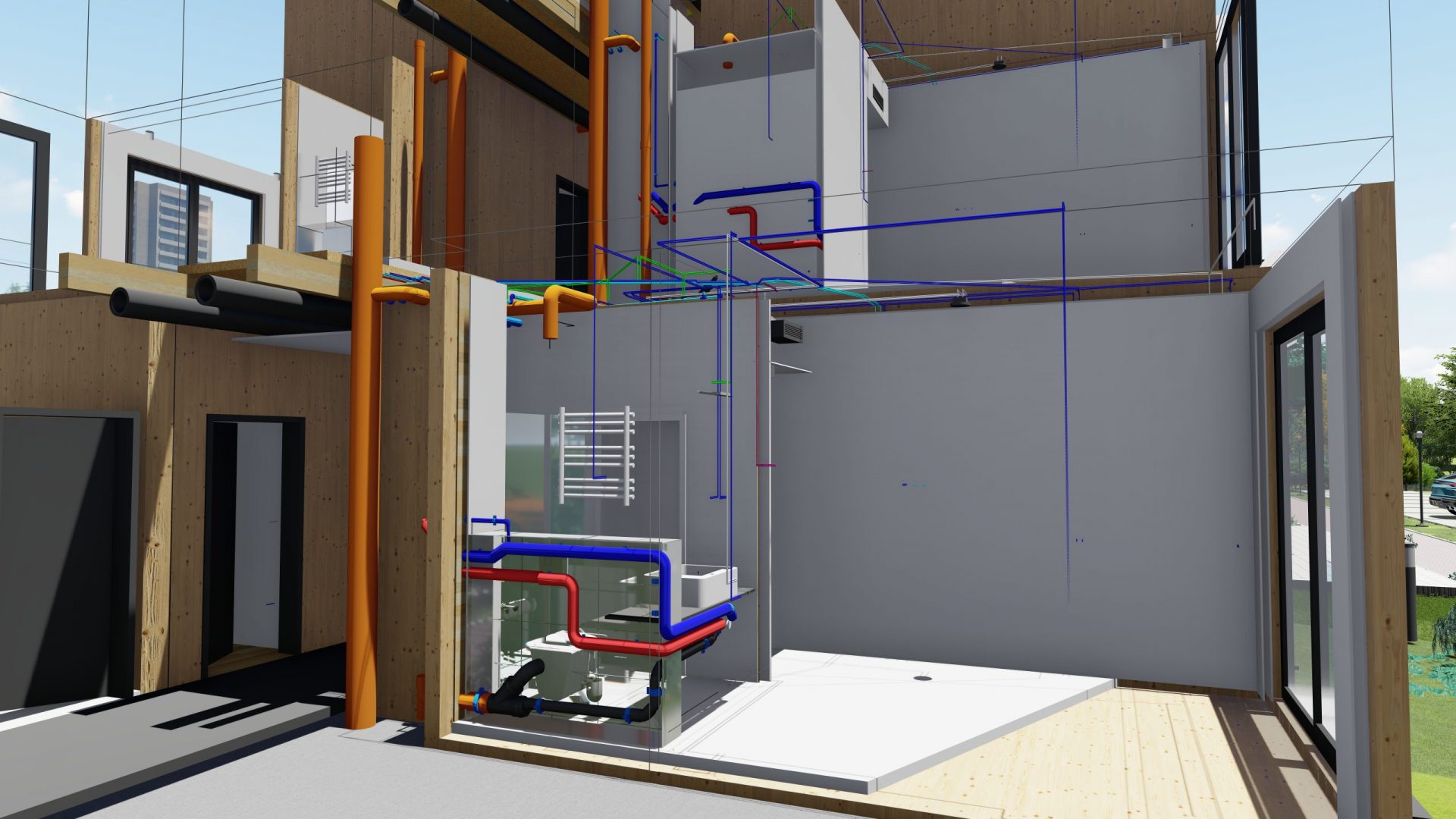

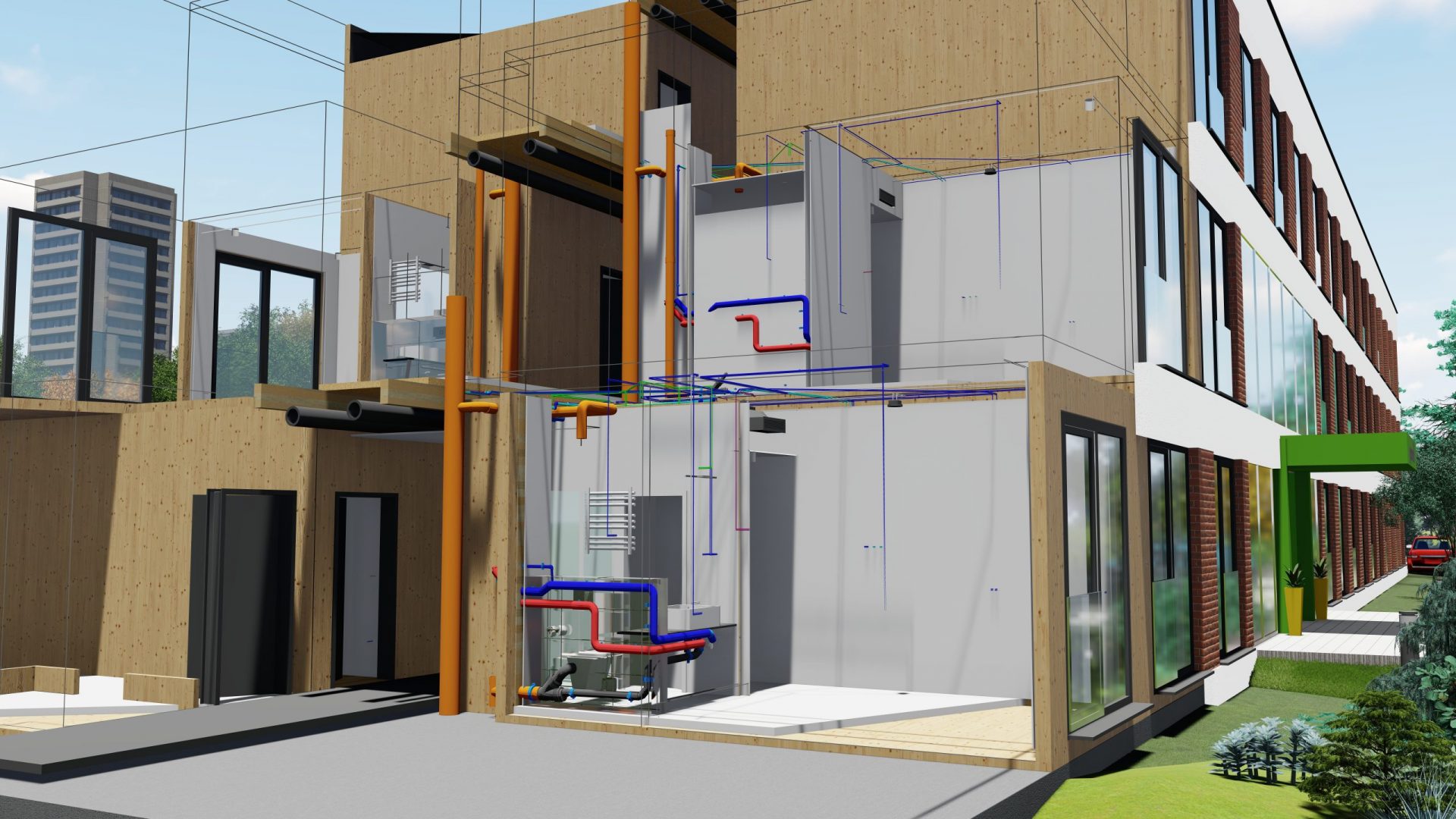

The work on the construction site is limited to earthworks, foundations, assembly of modules, facades and connections of installation shafts.