We are a family business that manufactures modules in CLT technology in solid timber construction. For over 20 years, the name Grzegorz Kopaczewski has stood for progress and development in timber construction elements with various project companies.

The Kopaczewski family has built up the Green Modul company based on its many years of experience in timber frame construction and has constantly developed it further. The many years of experience in the production and distribution of timber construction elements is the foundation of Green Modul sp. z o.o.

In 2015 / 2016 Feng prepared the modular technology with CLT for the Green Module. The timber construction was further developed and the form of solid wood construction with CLT is the result of this development. The many years of experience in timber frame construction and the implementation of numerous projects in Germany, Holland, Austria and Sweden have been incorporated into the concept. Preparations for the new technology based on solid wood panels (CLT) began in 2015/2016. This sustainable and stable construction, finished modules including TGA and interior design, fire protection certification (walls / ceilings / floors) is the basis and quality assurance for the Green Module concept. MPFA Leipzig was certified for the first time in 2019. In 2021 there was a certification over REI 90. Since 2020, these modules based on CLT board have been manufactured in the factory and an annual capacity of 48,000BGF has been achieved.

Today, GM specializes in solid timber buildings with a high degree of prefabrication and acts as a manufacturer for clients and investors. Green Modul realizes innovative, high-quality solid timber buildings in modern architecture and builds sustainable living and working spaces for modern society.

Modular timber construction enables a sustainable construction method with a considerably shorter construction phase. The timber modules can be produced in large quantities and with a degree of prefabrication of over 70-90%. Modern timber construction is ideally suited to serial construction such as modular timber construction. Large construction projects can be erected in the shortest possible time and, in addition to rapid completion, allow the property to be used sooner.

Climate protection

Sustainably ecological

The positive CO2 balance speaks for a traditional construction method with a natural material from sustainably managed European forest areas. The term “sustainability” was invented in forestry in the 18th century.

At that time, the forests were overexploited, because wood was the most important raw material. Since then, to ensure sustainable forest management, no more trees have been felled than planted.

Thermal insulation

Load-bearing wood products have very good thermal insulation properties and a very high load-bearing strength based on their own weight. The usually multi-layer component structures allow optimal adaptation to the respective requirements of fire, heat and noise protection. Wooden components can therefore be made very slim with an increase in usable space.

The factory

The main focus of our activities are the Western European countries, especially Germany.

Green Modul is based on universal principles and values that give our customers a feeling of security and give us the position of a reliable and trustworthy partner.

We carry out our tasks in accordance with the highest ethical standards and ensure the success of the investment and customer satisfaction.

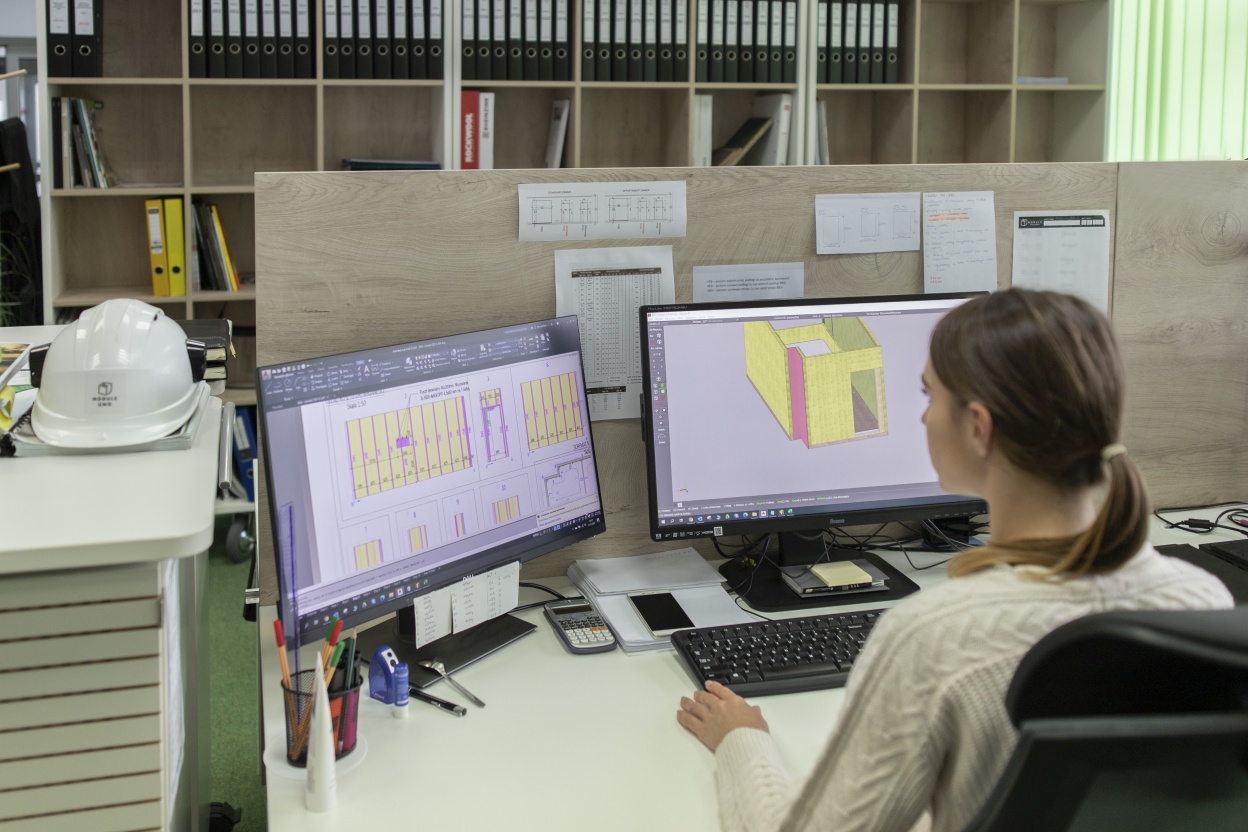

Scope of work

Before we start working together and sign a contract, we always precisely define the scope of work and the type of materials and solutions used.

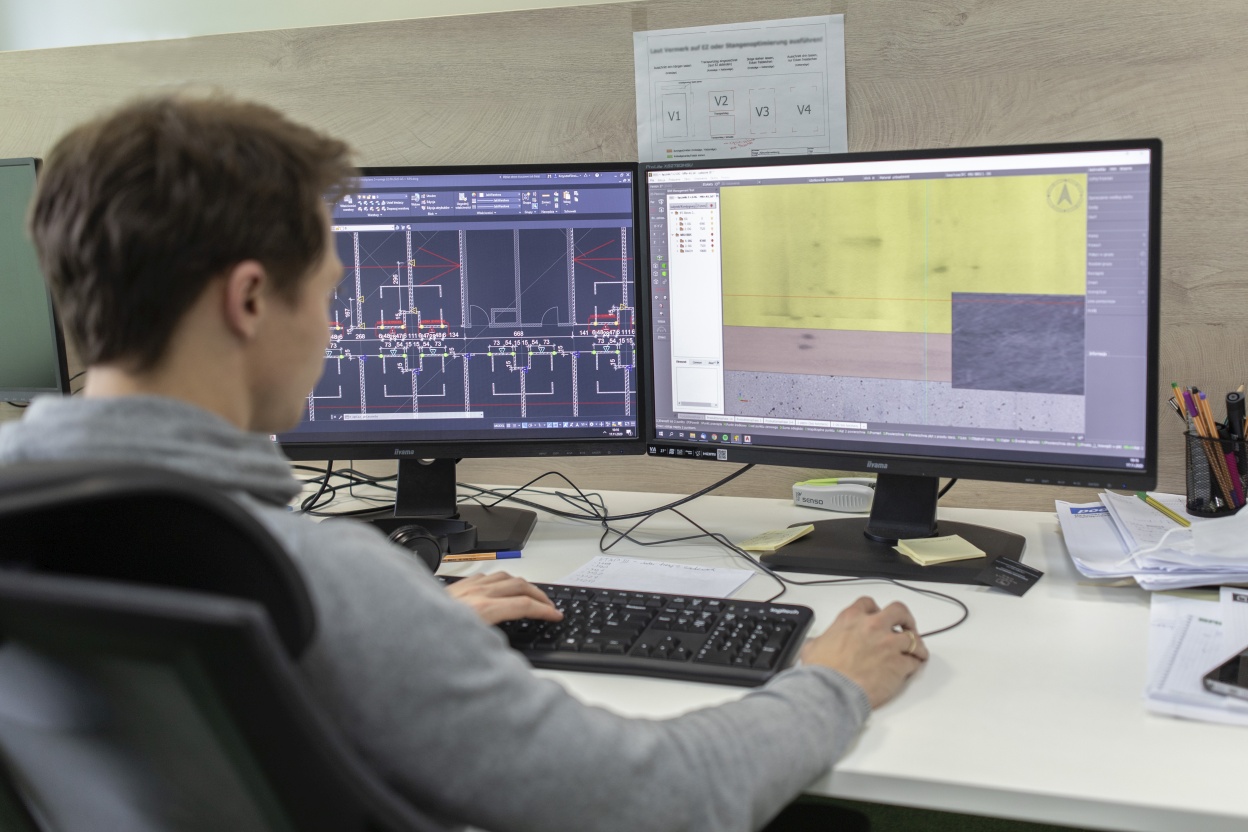

Controlling

The construction work is carried out under the constant supervision of the technical staff. A group of trustworthy employees and subcontractors enables work to be carried out efficiently, always of the highest quality.